How does a Putzmeister Sika 500 actually get underground?

- 05/19/2022

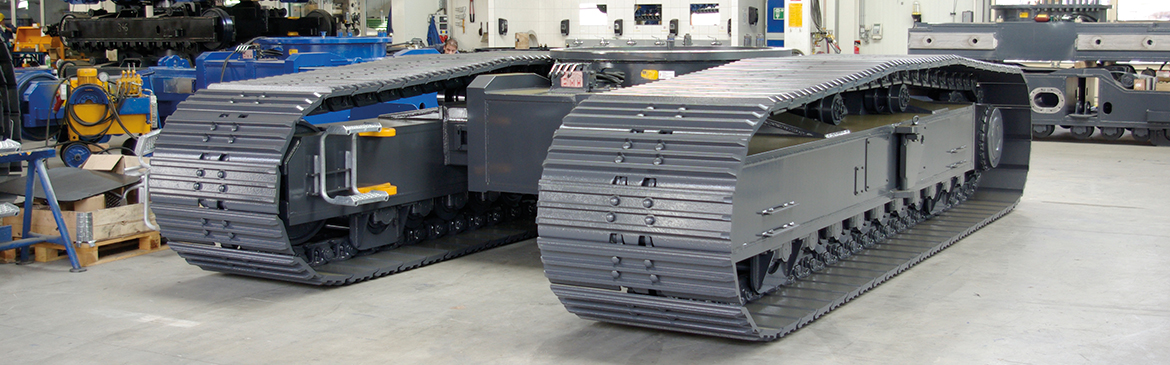

Salzgitter - At the beginning of the year, a so-called shotcrete buffalo was needed for the installation of the concrete inner lining in the Konrad shaft. To transport such large equipment underground, it has to be dismantled and reassembled underground. In theory, this sounds quite simple, but in practice, such a transport of large equipment requires some know-how. For the team led by Tommy Kammer from Maschinentechnische Ausrüstung, this is part of their daily business. After the inquiry to MTA in mid-November 2021, the team set about planning the project. The first step was to check the possible unit size for hanging in the shaft, as the 17-ton equipment had to be broken down into individual assemblies accordingly. However, this check revealed that separating the base frame in the middle was necessary. Before the electrical connections were disconnected, an inventory was also made of the worn parts and the necessary repairs. The individual assemblies were then shipped to Salzgitter by two truckloads. There, they were moved about 1,000 meters underground via Shaft I. Once all the parts had arrived at the assembly site, assembly began at the end of January. In the first step, the frame had to be aligned and the welded joint on the basic unit restored. After that, the remaining assemblies could be mounted on the basic unit and the components wired or hosed. A new set of tires was also fitted, with a special foam filling to prevent breakdowns in the shaft.

Commissioning took place underground at the end of February, followed by handover to the miners. "The new MTA ended this project as a test with positive conclusions and thanks all those involved," says Tommy Kammer, looking back with satisfaction on his team's performance.

German

German