Shaft sinking and new exploration

Small-profile roadway drivage in chrome ore mining in Kazachstan

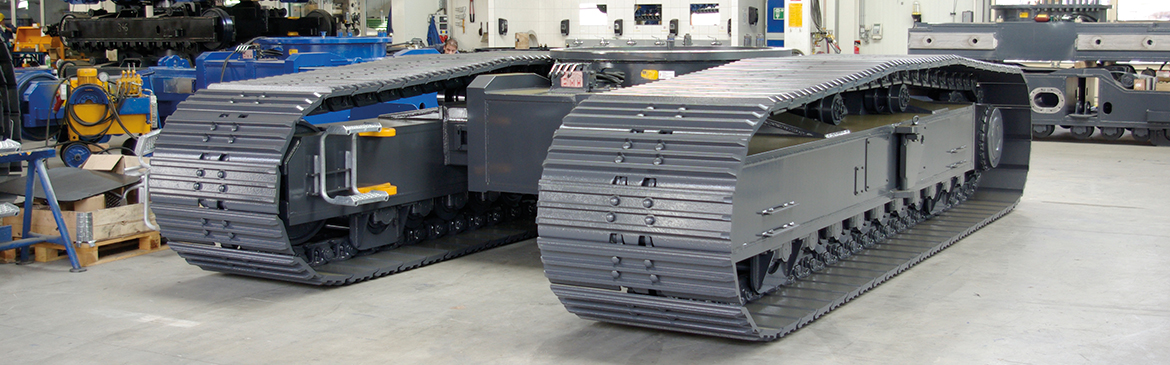

Roadway drivage works of the project “producing a road on the level of -480m in mine – 10th Anniversary of Independence of Kazakhstan – subsidiary of AO TNK Kazchrome” has implemented since August 2013. To develop a new working area, it is necessary to make a connection passage between hauling shaft and ventilation shaft of the mine. Additionally to the actual roadway drivage, the production of diverse crosscuts and roadway junctions is part of the order. In the most difficult geology, more than 3000 m connection passage has been drifted with a 13,5m2 cross section so far. Most of the roadway drivage to date has taken place in a serpentinite, the slickenside surfaces of which covered with talc have resulted in conjunction with groundwater entering sewers an extremely fractured rock. Constantly changing rock conditions and initial difficulties in ordering services from the client caused the greatest difficulties in the execution of the continuous roadway drivage. However, it was proven that high quality and durable structure can be made by the chosen technology of a mechanized heading (2 armed drill jumbo AtlasCopco Rocket Boomer 282, tunnel and loading excavator ITC TEREX-SCHAEFF 120 F4 as well as shotcrete technic MEYCO Oruga combined with a Putzmeister concrete pump). The roadway drivage is done by drilling and blasting whereas the knowledge of the “new Austrian tunneling method” is practiced. After the blasting, the initial securing is executed by a steel fiber reinforced wet shotcrete. The final concrete support happens in paving thicknesses between 5 and 20 cm, which depends on the geological conditions. The ultimate support will be finalized right after the evacuation of the excavated material. Rock anchors are assembled additionally to the shotcrete to minimize convergences. Therefore, so far occurred convergences in cleft and the irregular rocks are negligibly small compared to the road zones drifted by the utilized roadway drivage technology of the client up to now. The rail-bounded accumulated debris, as well as the transport of equipment, material, and device equipoised so that the reliable supply of the drifting site is assured.

At the same time, the provision could be arranged with local supplier despite tough purchasing conditions and insufficient qualities in the beginning. At present, the further substitution of the German supplies through the local solution is being checked. Problems are repeatedly caused by the disproportionate high coordination effort of the processes and procedures compared to the German project experience, both on technical matters and planning and billing. The differences in mentality, culture, and economic basic system make the daily work of the project not easy.

How to find us

SCHACHTBAU NORDHAUSEN GmbH

Industrieweg 2a

99734 Nordhausen

Telephone: +49 3631 632-0

Fax: +49 3631 632-334

E-Mail: sbn@schachtbau.de

Web: www.schachtbau.de

Copyright © , All Rights Reserved

German

German