Since the founding of the company, mechanical engineering has largely defined our services, which are complemented by preceding design and subsequent worldwide service. This customer-oriented range of services establishes SBN as a well demanded partner.

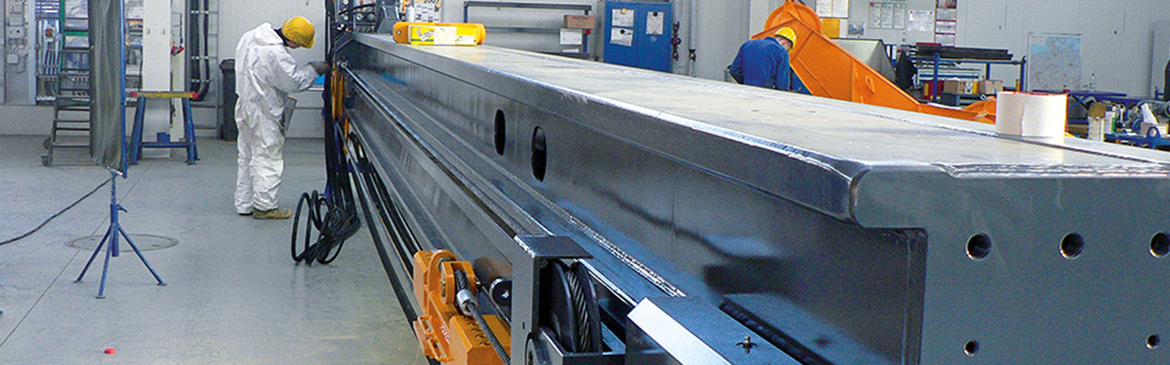

Our modern workshop, combined with the competence of our skilled personnel in the areas of welding, corrosion protection and assembly technologies ensures that the highest quality standards are met.

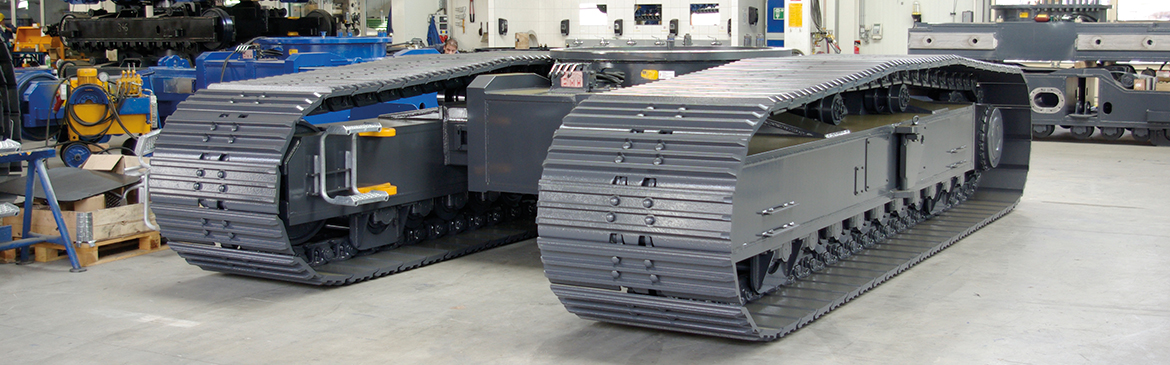

Client-optimized processes of design and production of structural steel elements, weighing up to 100 tonnes per unit, for civil engineering, industrial plants and shaft equipment are realised in our over 40,000 sqm large production halls. Furthermore, we fully manufacture and assemble the components and equipment for special foundation, construction and mining industry. Construction and reconstruction of machines and equipment, corrosion protection in the factory and on site, as well as worldwide service and repairs make our range of services complete.

These facilities, along with our technical department, make SBN a sought-after manufacturer and supplier for clients who expect cost-efficient and effective service.

Our extensive vertical integration of specialized services in areas of cutting, metal working, welding, machining, coating and assembly guarantee the quality of our work. Manufacturing, assembly and implementation of special projects make the range of services of mechanical engineering complete.

SBN, with its continually optimized and flexible production, meets the high demands of its clients from a variety of areas like construction and construction equipment industries or even the automobile and energy sectors. Each product is thus implemented as an individualised and cost-efficient solution.

German

German